- TOP

- ALCONIX at a Glance

ALCONIX at a Glance

Who we are

English subtitles available

The ALCONIX group is a comprehensive solution provider that combines two capabilities: trading of non-ferrous metals such as aluminum and copper and manufacturing of highly competitive niche products. While rolling out these two capabilities independently, we ultimately generate significant power by strengthening each, enabling us to realize our mission of “Drawing the Future of Our Dreams.”

Future vision

ALCONIX Group's

Long-Term Management Plan

and Purpose/Vision

The ALCONIX group in numbers

Proportion of outside directors:

Proportion of female officers:

Officers: Directors and Audit & Supervisory Board members

Ordinary profit

Regional sales weighting

Aggressive development of overseas business underpins ALCONIX’s strength

ALCONIX group’s strengths

Leveraging unique M&A expertise, we nurture and develop manufacturing companies that have joined our group into growth drivers. This enables us to provide end-to-end support—from raw materials and products through processed and manufactured products—in sectors with growing markets due to the electrification of vehicles, digital transformation (DX), and advances in IoT.

Our group’s technologies and products support IoT, DX, and a sustainable society

three focus areas

Automobiles, semiconductors, and electronic materials form an integrated business flow

-

Automobiles

Materials for EVs and FCVs Electric vehicles (EVs) and fuel cell vehicles (FCVs) and automotive electrification and IoT are accelerating the use of semiconductors and electronic materials

-

electronic materials

Battery materials

Materials Smartphones

TabletsDemand for high-performance electronic materials increasing in step with advances in DX and IoT

-

semiconductors

Semiconductors

Semiconductor

manufacturing

equipmentDemand for semiconductor production and mounting equipment growing as semiconductor applications expand

Our product lineup

Everything from raw materials and products (wrought copper products, electronic and

battery materials, minor metals) to processed and manufactured products

About ALCONIX's Business

One-stop manufacture, wholesale, and recycling of non-ferrous metal materials and parts.

We offer added value individual companies cannot provide on their own.

Trading

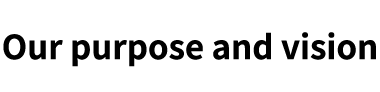

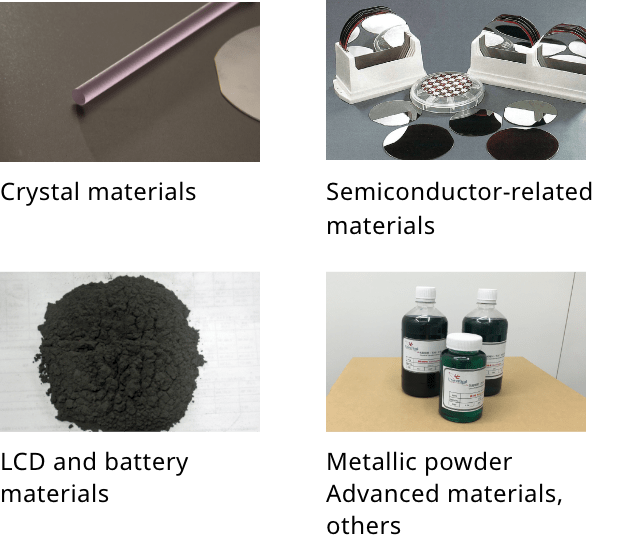

Electronic and Advanced Materials

We handle electronic materials and components and high-performance materials as well as minor metal and rare earth inputs.

Key capabilities

- Materials supply

- Parts supply

Aluminum and Copper

We handle base metal (aluminum, copper, nickel) parts and materials and metal recycling.

Key capabilities

- Parts supply

- Recycled metal lump recovery(recycling)

Main end products

Dark colors indicate our three focus areas

and FCVs

tablets

IT devices

(for vehicles, IT devices, etc.)

(materials

for steel manufacturing)

(body)

(aluminum frames, etc.)

(structural parts)

(for semiconductors)

(copper tubes)

Manufacturing

Equipment and Materials

Under our motto of “bringing science to quality assurance,” we produce materials for automobiles and semiconductors and testing and measurement equipment and materials.

Key capabilities

- Surface treatment

- Non-destructive testing

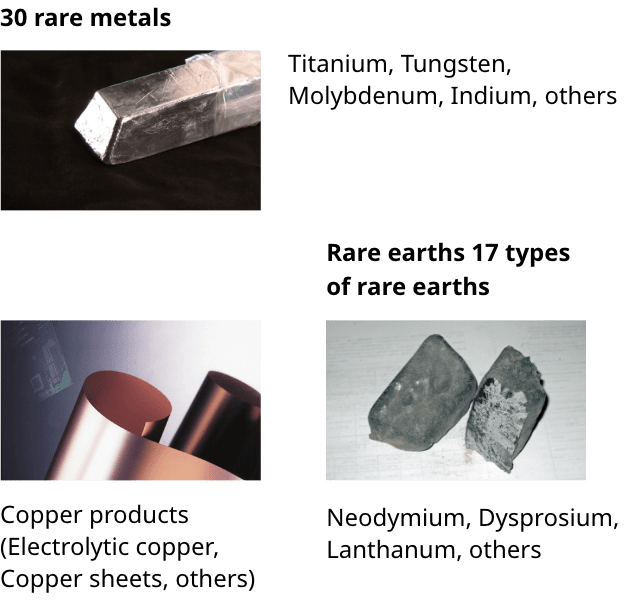

Metal Processing

Producing high value-added processed metal parts for automobiles, semiconductors, and IT equipment using some of Japan’s leading manufacturing facilities and superior technological capabilities.

Key capabilities

- Stamping

- Machining

- Grinding

Main end products

Dark colors indicate our three focus areas

(plating・friction modifiers)

(marking equipment)

(plating materials)

(PWB plating)

(non-destructive testing)

absorbers

(driving parts, trial parts)

tablets

(engine part)

(heat exchangers, various parts)

ALCONIX’s M&As

An M&A System That Promotes CSV Management

Mergers and acquisitions (M&As) are a key driver of growth for the ALCONIX Group. In light of this, we have established an M&A system that promotes CSV management,* pursuing social and economic value.

While ALCONIX’s advanced technology is specific to certain sectors, we have contributed to Japanese manufacturing by ensuring the business succession and subsequent growth of small to medium-sized companies that lack successors and investment capacity, highlighting them as acquisition targets.

To boost profitability, we also promote M&As of companies that can complement the capabilities of current Group subsidiaries. This two-pronged strategy, which emphasizes both business succession-focused M&As and complementary M&As, aims to create sustainability for ALCONIX.

Creating shared value:

A managerial concept in which a company benefits economically through activities to resolve social issues