- TOP

- Sustainability

- Solving Social Issues through Business

Solving Social Issues through Business

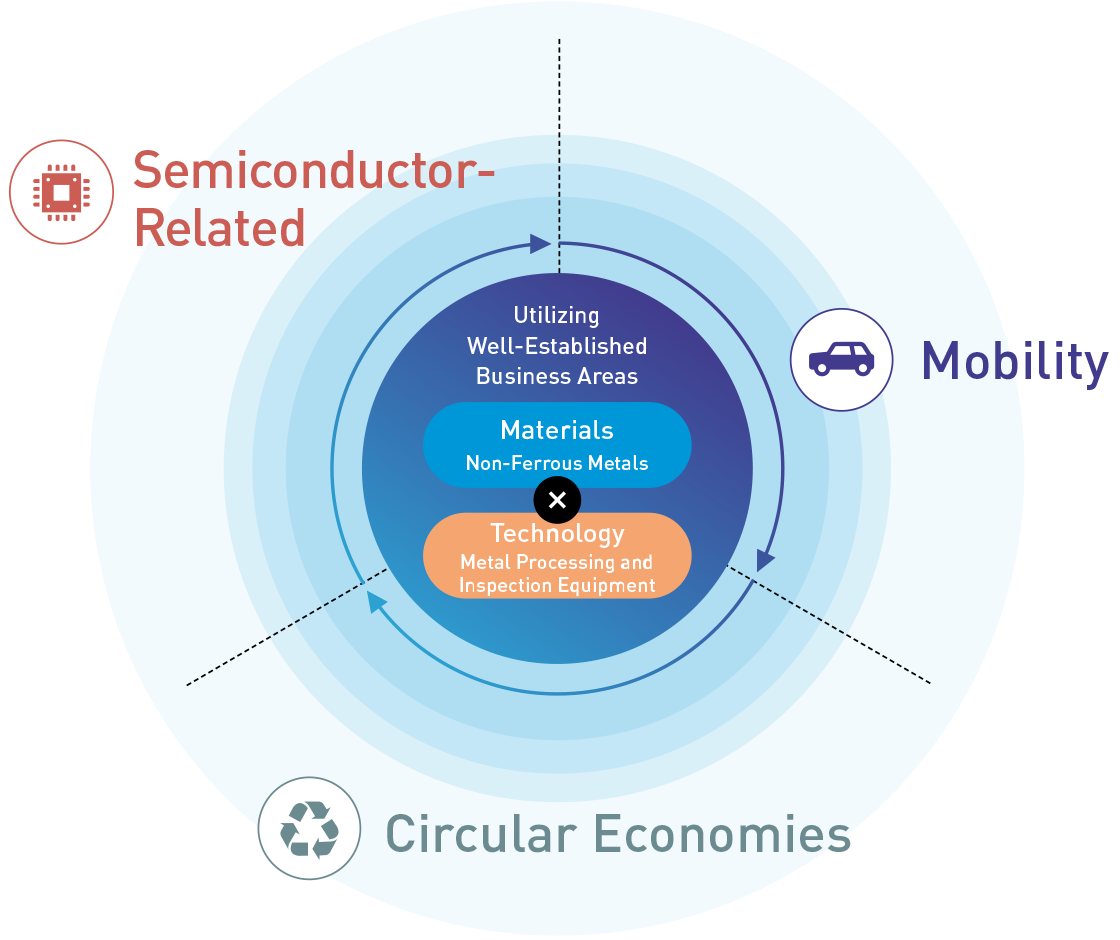

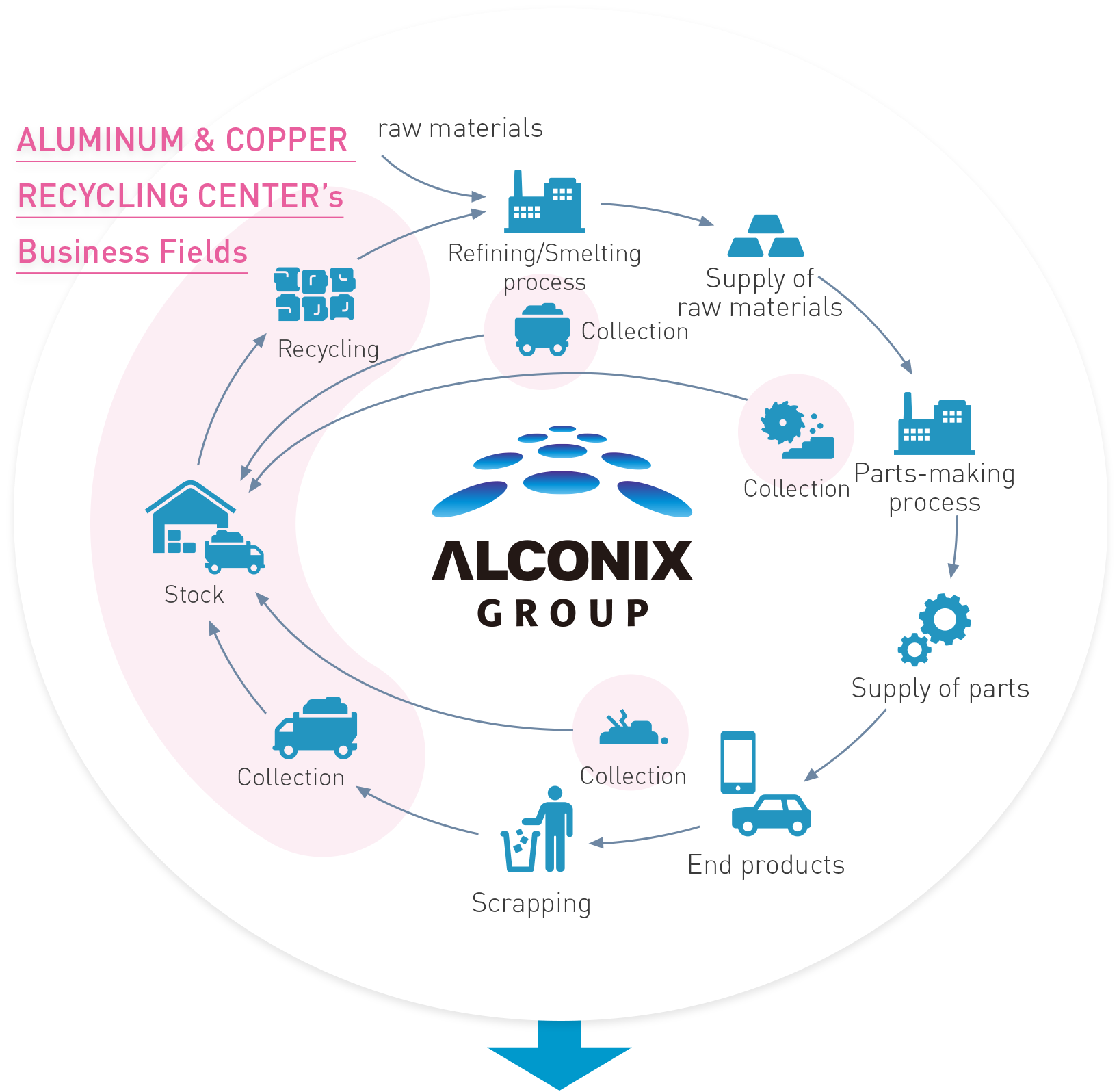

The ALCONIX Group has highlighted “circular economies” as a strategic growth area under Medium-Term Management Plan 2024. As part of the ALCONIX Group, which aims to help create a recycling-oriented society by building environmentally responsible businesses, ALUMINUM & COPPER RECYCLING CENTER plays a central role in realizing a resource-recycling society by contributing to the recycling of non-ferrous metals.

Businesses Related to the 3Rs

Our Group, aiming to contribute to the creation of a recycling-oriented society by building environmentally responsible businesses, has positioned the promotion of the 3Rs (Reduce, Reuse, Recycle) as one of the core elements of our operations and is putting it into practice in various ways.

Resource Recycling Business

ALUMINUM & COPPER RECYCLING CENTER is engaged in the recycling of aluminum, copper, and other recyclable resources (from collection to sale) with bases in Osaka and Kitakyushu area.

The Osaka head office mainly handles recycled aluminum resources, and has one of the largest resource recycling yards in the Kansai region. The Kitakyushu branch mainly handles copper.

Competitive Advantages

① Leading Domestic Collection Capabilities

For customers requiring large amounts of recycled resources at once, the ability to handle large volumes is an advantage. ALUMINUM & COPPER RECYCLING CENTER, with one of the largest facilities in Japan, possesses the capacity to meet the diverse needs of its customers.

② The Power of the ALCONIX Group’s Sales Capabilities

The brand power and extensive customer base of the ALCONIX Group are strengths. Moreover, the Group leverages sales expertise developed in the trading industry to communicate the importance of using recycled resources to customers and provide products tailored to their needs.

③ Job Skills That Supports High Quality

ALUMINUM & COPPER RECYCLING CENTER has on-site experts who can visually inspect materials and produce high-quality recycled resources following a meticulous sorting process.

ALUMINUM & COPPER RECYCLING CENTER utilizes both the resource recycling yard in Hirakata, Osaka Prefecture, and the resource recycling yard in Kitakyushu city, Fukuoka Prefecture, aiming to become the largest collector of non-ferrous metal scrap in Japan.

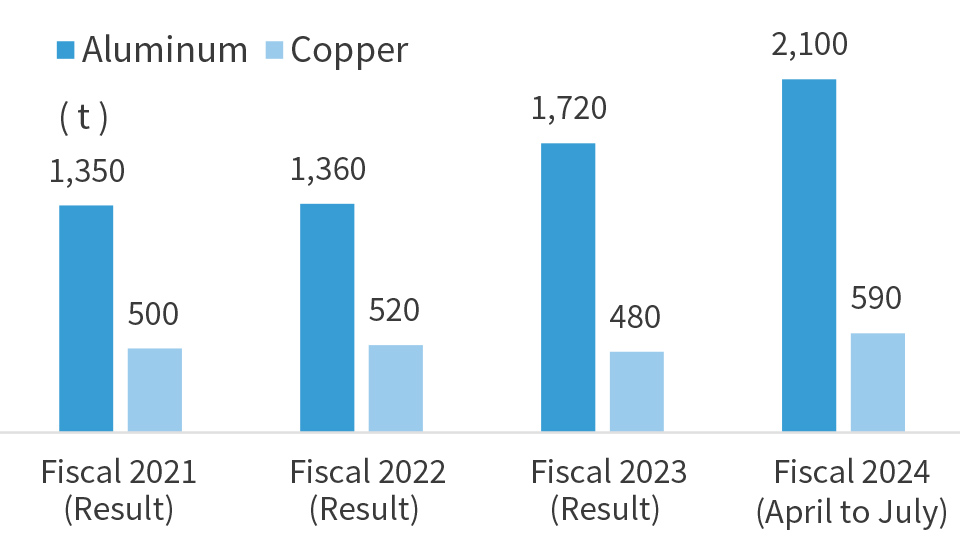

Amount of Aluminum and Copper Collected

at ALUMINUM & COPPER RECYCLING CENTER

Reduce:TOKAI YOGYO

TOKAI YOGYO specializes in overlay welding that contributes to the longevity of molds and equipment by improving durability and resistance to wear and corrosion. The company manufactures and sells welding materials used for newly designed press molds, and for the repair of press molds, die-casting molds, and forging molds. As automobile production makes a global shift toward EVs, TOKAI YOGYO is expected to play a part by helping create the molds for one-piece molding in aluminum die casting, a manufacturing process that will support EV production in the future.

Reuse:FUJI PRESS

FUJI PRESS manufactures precision stamped parts for automobile powertrains and excels in high precision and highly advanced processing. In addition, the company is working diligently to reduce its environmental impact through the 3Rs. One example directly related to the SDGs involves the coating oil applied to products to protect metal from rust and corrosion, which is removed prior to shipping and reused. In fiscal 2022, we began using less hazardous, more environmentally friendly cleaners and degreasers for this process. In addition, initiatives such as in-house production of oil tanks with filters, which increase the amount of oil that can be reused, enabled the company to reduce its amount of newly purchased reusable oil by 85%, or approximately 2,500 liters, compared with fiscal 2021. In fiscal 2023, the company intends to apply oil filtration to other processes within its factory, and expects this change to reduce total oil use by a further 4,000 liters.

Decarbonization-Related Businesses

In recent years, a growing amount of attention has been given to heat pumps as a means to adapt to*1 and mitigate*2 climate change, and demand for heat pumps as a form of temperature control is on the rise. In the EU, the rise in demand has been particularly sharp for heat pumps as a heating solution, since natural gas accounts for power used in heating at a rate approximately double that of electricity.*3 Research has shown that if approximately 35% of all heating equipment in Europe were replaced with heat pumps, energy consumption could be reduced by approximately 36% and CO2 emissions by approximately 28%,*4 making heat pumps an increasingly important contributor to decarbonization and energy security.

Based on these market trends, we are working with a number of Japanese air conditioner manufacturers to promote the development of HVAC-related businesses. Specifically, we will support the development of supply chains for each customer that intends to increase production in Europe, and diversify the items we provide. Through these actions, we aim to increase the transaction volume of Group businesses related to this field above the rate of market growth. In addition to the developments in Europe, Japan is also expected to make a shift toward refrigerators and freezers that use CO2 as a refrigerant, which has a smaller impact on global warming than existing equipment. The ALCONIX Group is committed to maintaining and further developing Japan’s cold chain*5 by handling copper tubes essential to this transition. These are some of the strategic steps we will take to develop the Group’s HVAC related businesses as part of Group CSV management.*6

- *1 Responding to the various changes in the environment as a result of climate change

- *2 Taking measures to suppress climate change

- *3 The Future of Heat Pumps, International Energy Agency (IEA)

- *4 The Heat Pump Wave: Opportunities and Challenges, the European Commission’s Joint Research Centre

- *5 A form of logistics which ensures that products requiring temperature control (fresh foods, pharmaceuticals, etc.) are kept at low temperatures during production, transportation, and consumption

- *6 Creating shared value: A managerial concept in which a company benefits economically through activities to resolve social issues

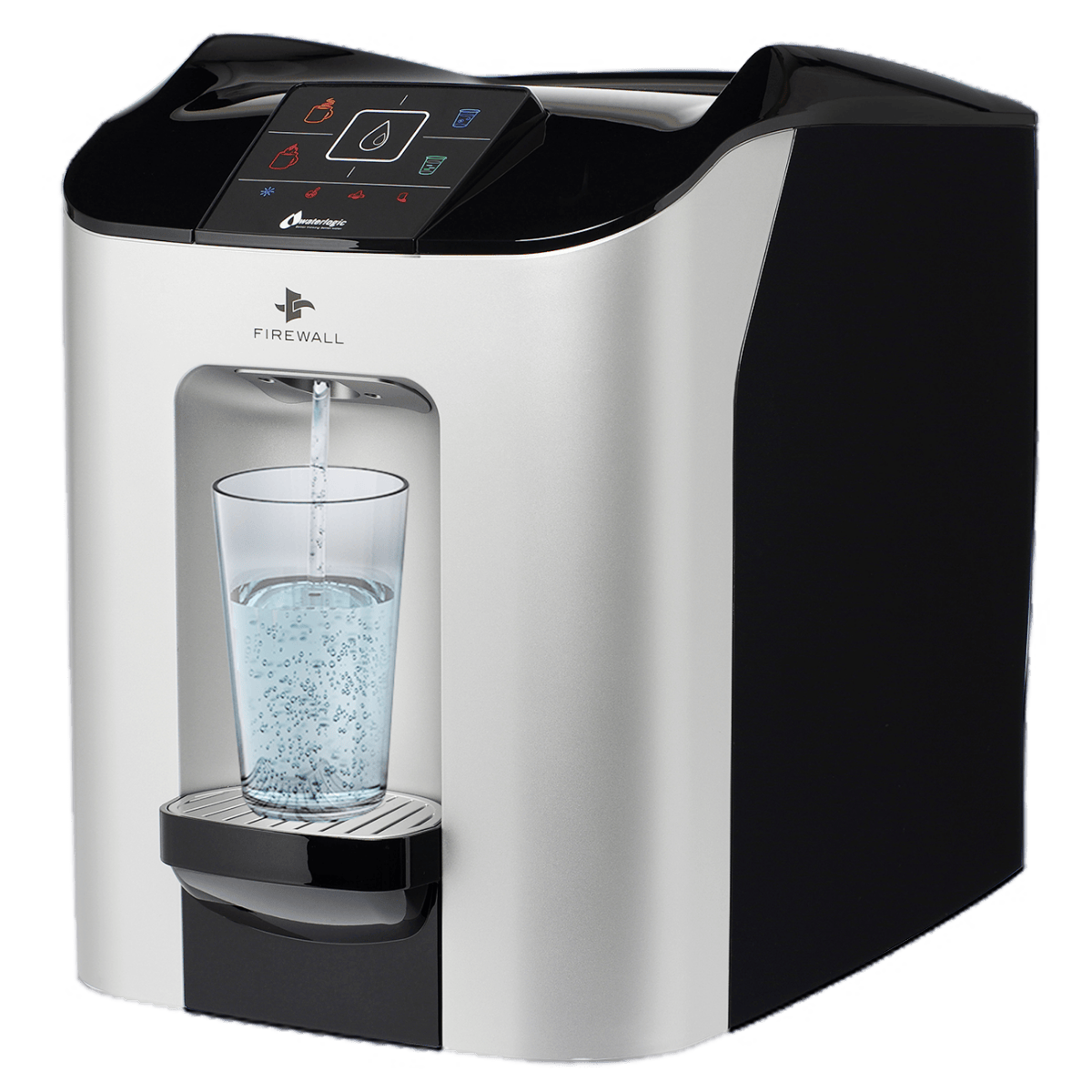

Reduction of Plastic Waste

Our Group handles Waterlogic, a plumbed-in water purifier that delivers safe water at low running costs, under the motto "Better thinking, better water™" Companies are increasingly reviewing their plastic usage across operations to address microplastic pollution and reduce CO2 emissions. Taking the lead in making such products widely available, we are actively working to preserve the global environment, starting with the familiar resource of “water."

Waterlogic is a water purification dispenser that originated in the UK. With a strong focus on environmental sustainability, it reduces waste from plastic bottle replacements, conserves resources, lowers CO2 emissions, and minimizes environmental impact. This sustainable product also reduces water and energy usage, minimizes waste, and ensures the efficient and prolonged use of limited resources.

In addition, it adopts a highly effective purification system that removes over 99.99% of bacteria and viruses, providing safe and reliable water.

Taking advantage of these characteristics, we are promoting the “Go! Plastic Smart with Waterlogic” project, which also serves as a Group-wide initiative for contributing to local communities.

Toward a Bottle-Free Future

Waterlogic is bottleless (plumbed-in), eliminating the need for the production, transportation, and recycling of plastic bottles, and significantly contributing to CO2 reduction. By minimizing the plastic waste generated from bottle replacements, it is possible to balance the achievement of SDGs with cost benefits.

We also offer services that are designed and manufactured for use in large-scale environments such as offices, factories, hospitals, restaurants, hotels, and schools. As a result, significant contributions to the environment, such as reducing plastic waste, can be expected.