- TOP

- Media

- ALCONIX's BluePrint

- Offshore Wind Power Generation + Hydrogen! Titanium & New Materials Department Breaking into New Fields

Offshore Wind Power Generation + Hydrogen! Titanium & New Materials Department Breaking into New Fields

ALCONIX originated from the non-ferrous metals department of the former Nissho Iwai, a general trading company. The company name, ALCONIX, is derived from the AL of aluminum, the CO of copper, and the NI of nickel, combined with the letter X to symbolize the future and our commitment to exploring new frontiers. We create added value by integrating our trading capabilities, which focus on raw materials, with our manufacturing operations that produce finished products. ALCONIX supports the development of future technologies, such as electric vehicles (EVs), hydrogen-powered fuel cell vehicles (FCVs), batteries, and semiconductors, by sourcing high-performance materials globally and delivering them in their most optimized forms.

In Dreamers' Voice, this new series of columns highlighting ALCONIX's diverse business activities, we showcase how the company is bringing its corporate slogan—Drawing the Future of Our Dreams—to life. In the first installment, we introduce the Titanium & New Materials Department, which is breaking into new fields.

What Is Titanium Made From?

Iron and copper are produced by melting iron ore and copper ore at high temperatures. But what about titanium? Is there titanium ore? While titanium is well-known for being lightweight and strong, its origins and practical applications are less familiar to many.

“The raw material for titanium is primarily a mineral called ‘rutile,’ which is mined in Africa and Australia. This beautiful mineral contains titanium, which is extracted through complex chemical reactions. While titanium reserves are abundant on Earth, the vast majority is used as titanium dioxide in products such as pigments. Metallic titanium accounts for only about 5% of the total titanium market,” explained Mr. Kenichiro Okura, head of the Titanium & New Materials Department.

Mr. Okura, who joined ALCONIX in 2001, was promoted to department head in October 2023 at the age of 44. He possesses deep knowledge of titanium, from its raw form as rutile to its diverse applications.

In our daily lives, it has become commonly used in products like eyeglass frames.

Titanium has the four following major features:

-

Lightweight and strong

-

Corrosion-resistant

-

Gentle on the human body

-

Excellent heat resistance

These qualities have led to its widespread use in various applications

Titanium's greatest feature is that it is twice as strong as steel, yet has a specific gravity (grams per cubic centimeter) of 4.51, making it more than 40% lighter than steel. This combination of lightness and strength makes titanium ideal for use in aircraft, where these characteristics are critical, as well as in sporting goods such as golf clubs. Also, due to its high corrosion resistance, titanium is used in general industrial fields such as chemical processing and heat exchangers.

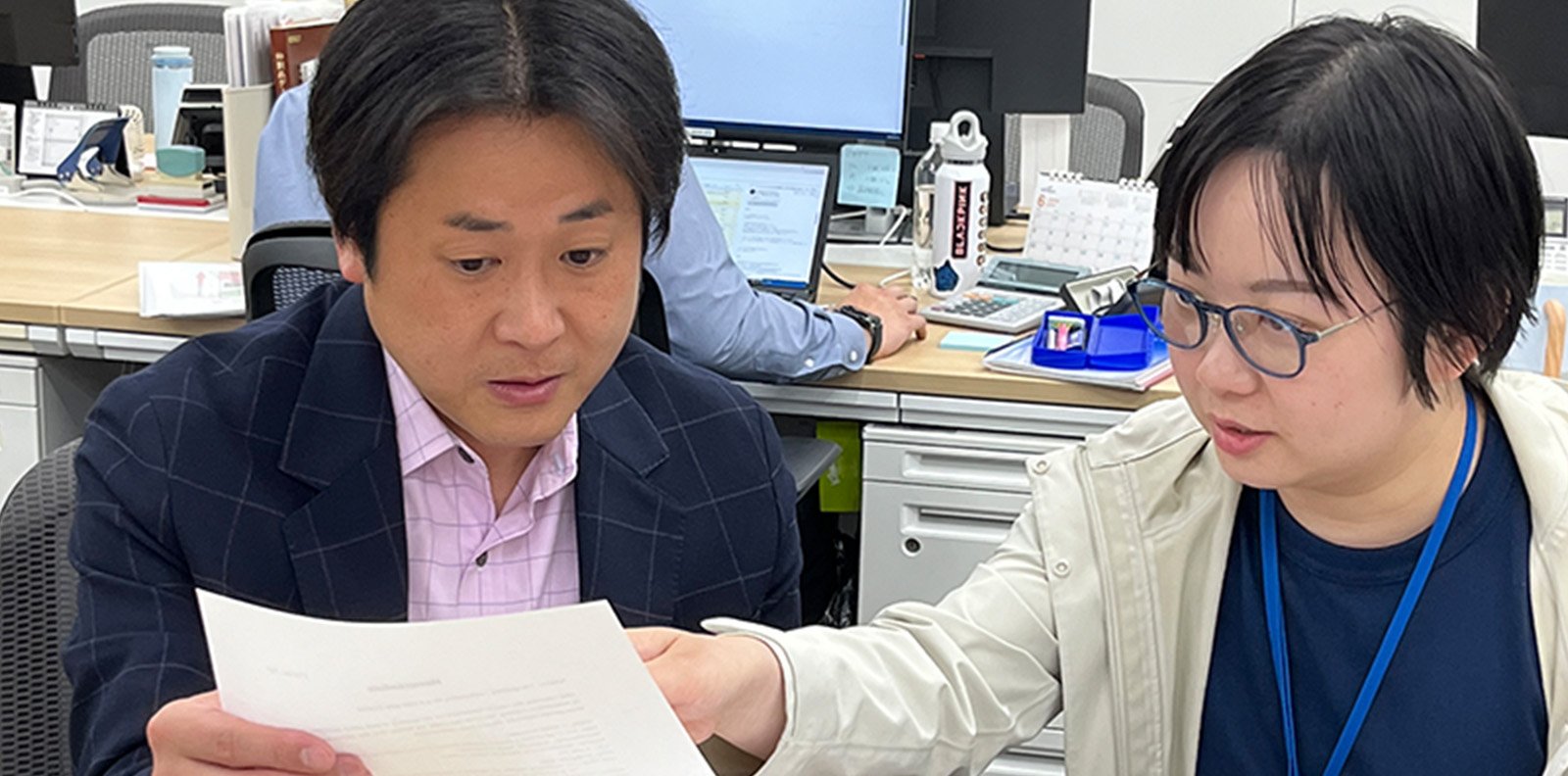

Furthermore, titanium has excellent biocompatibility, meaning it is gentle on the human body. As it has a low rejection rate by the human body, many medical devices, such as implants used in bone fracture surgeries, are made of titanium. Department Head Okura smiles and says, “Not only is titanium used for implants in bone fracture surgery for humans, but the titanium supplied by ALCONIX is also supporting the columns of the Acropolis in Greece to prevent them from collapsing. As it is a World Heritage site, that was a profoundly meaningful project for us.”

ALCONIX Titanium Is Also Used in Well-Known Ultra-Luxury Sports Cars

ALCONIX was established in 1981 when the non-ferrous metals department of the former Nissho Iwai was spun off into a separate company. In 2001, it became independent through a management buyout (MBO). The Aluminum, Copper & Titanium Division, which has carried on the company's original aluminum and copper businesses since its founding, comprises three departments. Among them, the Titanium & New Materials Department, as one of the departments responsible for ALCONIX's “X” (representing the future and the pursuit of new frontiers), has been in charge of titanium, a relatively new material, and has been working to explore new fields.

Rutile is processed by titanium manufacturers into a spongy intermediate form called “sponge titanium,” which is then melted and cast into titanium ingots. These are further processed into “roll flat products,” such as sheets and rods, by metal material manufacturers. These high-quality materials produced by Japanese manufacturers, together with ALCONIX's trading and distribution expertise in managing delivery schedules and shipping routes, are highly valued by overseas customers.

Representative customers to which ALCONIX supplies titanium include a Swedish heat exchanger manufacturer and a Slovenian exhaust system manufacturer. The Slovenian company, Akrapovič, is renowned for producing sports exhaust systems used in high-end sports cars. The Titanium & New Materials Department will continue to leverage the competitiveness of its products and the market insight cultivated through many years of trading experience, seeking further growth opportunities for the future.

Synergies Only Possible with the ALCONIX Group

As an initiative for the future, the Titanium & New Materials Department is also actively working to develop the fields of hydrogen and medicine. Collaboration with Group companies and highly specialized external partners plays a key role in this effort.

In the medical field, utilizing highly biocompatible titanium requires addressing the needs of physicians and adapting to evolving medical technologies. To this end, it is important not only to supply raw materials but also to develop the in-house capabilities to manufacture parts and products.

Since around 2009, ALCONIX has pursued an aggressive M&A strategy, expanding its Group beyond traditional wholesale and distribution operations to include medium and small-sized enterprises (SMEs) specializing in machinery and metal processing.

In the Titanium & New Materials Department, we are collaborating with OHBA SEIKEN CO., LTD. (Aichi Prefecture), which joined the Group in 2013, to explore and expand into the medical field. Combining ALCONIX’s expertise in titanium materials with OHBA SEIKEN’s precise machining and grinding technologies, we co-exhibited at Medtec Japan, a specialized trade show that brings together healthcare professionals and medical device manufacturers from across the country. We also expect synergies with Sakamoto Electric MFG Co., Ltd. (Fukuoka Prefecture), which joined the Group in July 2024, particularly in high-precision machining technologies for aluminum and titanium.

Toward a Hydrogen Society and the Future Beyond

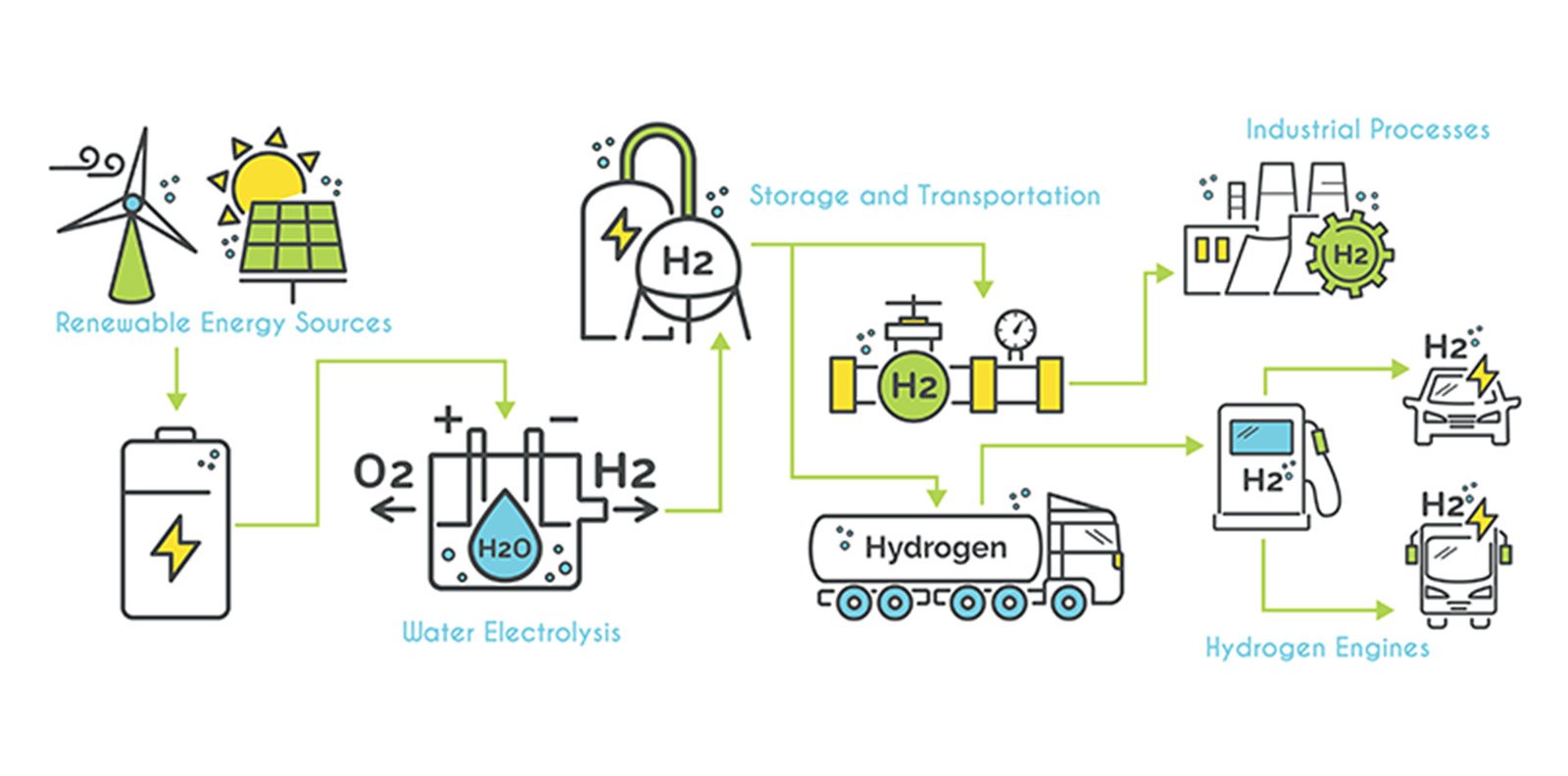

Hydrogen, another frontier of exploration, embodies our commitment to future innovation. Hydrogen does not emit carbon dioxide (CO2) when burned, and is attracting attention as a clean energy alternative to oil. Do you remember learning about water electrolysis in a science experiment in school? Hydrogen, which can be extracted from water, is an inexhaustible energy source. Practical applications of fuel cells (FCs), which generate electricity directly from hydrogen without combustion, have also been advancing.

Whether electrolyzing water or extracting electricity from hydrogen, the material of the electrodes determines the efficiency. A global development race is underway for electrode materials, with titanium and nickel currently gaining significant attention. Titanium is used in the core components of fuel cell vehicles, which are now seeing practical deployment.

ALCONIX has already started supplying titanium and nickel samples for a pilot plant operated by a European water electrolysis equipment manufacturer. Several projects have been launched in Europe to produce hydrogen using clean electricity generated from offshore wind power generation facilities.

Department Head Okura is drawing the future of our dreams, saying, “In his 1874 adventure novel The Mysterious Island, French author Jules Verne prophesied, ‘Water will one day be used as fuel.’ We aim to supply the raw materials to help realize this dream from 150 years ago and engage with the future that lies beyond.”

We will continue to present ALCONIX's business activities through our official media channels, and we encourage you to stay informed by visiting regularly.

Supported by NIKKAN KOGYO SHIMBUN,LTD.